A Healthy Inlet System Equals a Healthy Turbine

We know how important it is to have an inlet system functioning at peak performance. Our years of experience combined with our commitment to keeping up with current industry trends and technological advancements mean you can trust our judgment.

The Inlet System Process

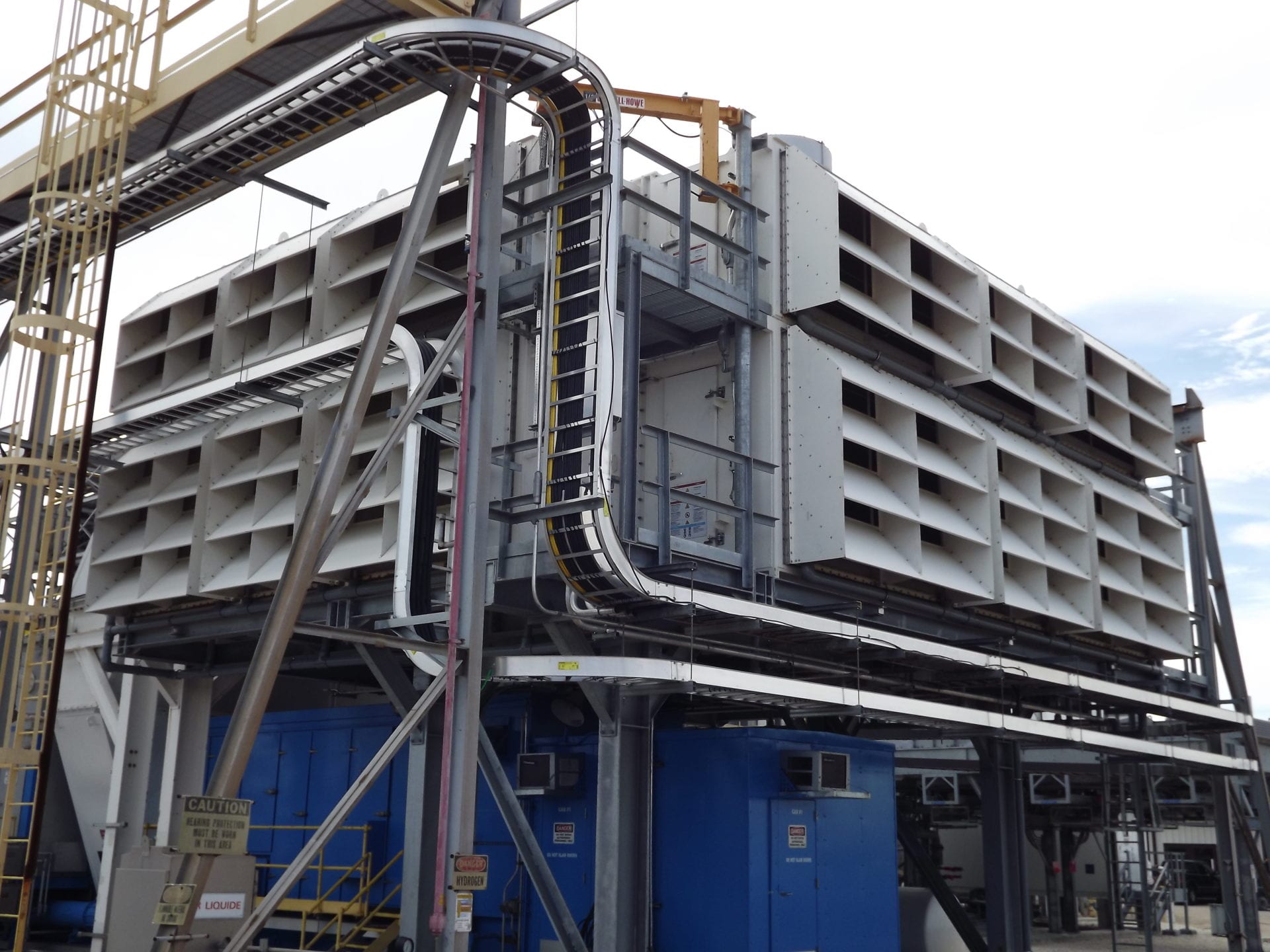

The function of the gas turbine air inlet compartment or filter house is to provide clean air to the gas turbine during the combustion process. The filter house draws air from the surrounding environment, and the first requirement is to ensure that large dust particles and moisture droplets do not enter the compartment. The air is filtered as it travels through the filter elements that are mounted inside the chamber. Then, the clean air is channeled into the transition section and exits the air inlet compartment through the transition flange into the inlet ducting system.

The air flows from the inlet ducting through the inlet plenum to the compressor and then into the gas turbine. The filtration system may be either a static or a self-cleaning design. One significant difference is that a self-cleaning system is capable of automatically cleaning the filter elements when the dust accumulation reaches a predetermined level based on the measured pressure drop across the filters, while the static system typically consists of pre-filters and final filters, which are replaced when dirty.

The filter house is also one of the possible places where the air can be cooled before entering the gas turbine. Cooler air is denser and therefore increases the turbine’s power output and efficiency by allowing additional fuel to be added to the combustion process. Optional cooling systems, like a media type evaporative cooler, may be integrated into the design of the air inlet compartment. Atmospheric air, as required in the gas turbine cycle of operation, is filtered before entering the turbine compressor.

An inlet air filter house is generally employed to remove solid foreign matter from the turbine inlet air while the inlet ductwork is in place to channel this clean air to the turbine compressor without compromising the integrity of the clean air. This ductwork is also designed to reduce the transmission of noise from the turbine compressor while keeping the pressure drop across the system to a minimum.

IPS can improve the performance of full GT inlet system, including:

- Filter House

- Inlet Duct

- Inlet Silencer

- Inlet Plenum